New vs. Used Forklift Cost Comparison: What You Save and Risk

Buying a forklift is a major investment for any business. Whether you’re operating a warehouse, construction site, or logistics company, your material handling equipment plays a big role in productivity and safety. One of the biggest decisions you’ll face is whether to purchase a new forklift or a used forklift. While the cost difference may be obvious, the long-term value and risk require closer evaluation.

This article breaks down the total costs, benefits, and drawbacks of both options. We’ll help you decide which choice fits your operational needs and budget while answering common questions around maintenance, depreciation, and resale value.

Upfront Cost Breakdown

Choosing between new and used forklifts starts with comparing sticker prices. Several other financial factors influence the total investment.

New Forklift Cost Overview

A new forklift generally costs between $15,000 and $100,000+, depending on type, size, and configuration.,

| Type | Cost | Work |

|---|---|---|

| Electric warehouse forklifts (3,000-4,000 lb capacity) | $15,000-$25,000 | Ideal for indoor use and minimal lifting requirements |

| LPG forklifts (5,000-6,000 lb capacity) | $25,000-$35,000 | A versatile choice for indoor/outdoor applications |

| Diesel forklifts (8,000-12,000 lb capacity) | $40,000-$60,000 | Built for tough outdoor tasks and heavy-duty lifting |

| High-capacity forklifts (15,000+ lb capacity)) | $60,000-$100,000+ | Used in ports, steel yards, and heavy manufacturing |

| Narrow Aisle Reach Truck | $25,000-$40,000 | Ideal for high-rack warehouse operations |

| Order Picker | $15,000-$30,000 | Designed for picking inventory at varying heights |

| Internal Combustion (IC) | $25,000-$60,000 | Powerful and suited for outdoor or rugged applications |

| Pneumatic 4-Wheel Forklifts (New) | $30,000-$65,000 | Built for rough terrain and outdoor use |

| Cushion Forklifts (New) | $20,000-$45,000 | Best for smooth indoor surfaces like warehouses |

| Electric Pallet Jacks and Stackers (New) | $3,500-$12,000 | Suitable for low-lift pallet movement in tight areas |

| High-Capacity Big Trucks (New) | $70,000-$120,000+ | Built for ports, heavy manufacturing, and steel handling |

Additional costs include:

- Custom features (e.g., fork positioners, cold weather packages): Add $1,000-$5,000.

- Advanced safety tech (e.g., stability sensors, rear-view cameras): Add $2,000-$8,000.

- Extended warranty plans: Cost $1,500-$3,500, depending on terms.

- Delivery and installation: Expect to spend $500-$2,000, depending on distance and dealer services.

These extras can increase the total new forklift cost by 10-25% over base pricing.

Cost of Used Forklift Options

The cost of used forklift models is typically 25% to 50% less than comparable new models, making them an appealing choice for cost-conscious businesses.

| Type | Cost | Work |

|---|---|---|

| Used electric forklifts (3,000-4,000 lb capacity) | $5,000-$10,000 | depending on age, battery condition, and hours |

| Used LPG forklifts (5,000-6,000 lb capacity) | $10,000-$18,000 | suitable for moderate indoor and outdoor work |

| Used diesel forklifts (8,000-12,000 lb capacity) | $18,000-$30,000 | often used in outdoor and industrial applications |

| Refurbished high-capacity forklifts (15,000+ lb capacity) | $25,000-$40,000 | designed for heavy-duty operations |

| Used Narrow Aisle Reach Truck | $10,000-$25,000 | depending on age and lift height |

| Used Order Picker | $8,000-$18,000 | based on model and battery life |

| Used Internal Combustion (IC) | $12,000-$35,000 | depending on hours and condition |

| Used Pneumatic 4-Wheel Forklifts | $15,000-$40,000 | for outdoor-capable machines |

| Used Cushion Forklifts | $10,000-$28,000 | for smooth indoor operations |

| Used Electric Pallet Jacks and Stackers | $2,000-$7,000 | depending on features and voltage |

| Used High-Capacity Big Trucks | $40,000-$80,000 | for heavy industrial applications |

These lower price points help small businesses or startups access reliable material handling equipment without straining their capital. Choosing to buy used forklift equipment can deliver major upfront savings while supporting long-term operational goals.

Operational costs

Maintenance:

- New forklifts: Generally cost less to maintain early on, especially during warranty coverage. Most new forklifts won’t require servicing beyond basic checks for the first 500 hours. After that, routine service costs are modest-around $500-$1,000 annually for light use.

- Used forklifts: Can have higher maintenance and repair needs depending on age and usage. If not properly maintained, they may require new tires ($300-$1,000), brake replacements ($500-$1,500), or hydraulic work ($800-$2,500).

- Estimated annual maintenance costs:

- Light-Duty Electric (1,200 hrs/year): $750-$1,200

- Mid-Duty Propane (1,500 hrs/year): $1,200-$2,000

- Heavy-Duty Diesel (2,000+ hrs/year): $2,000-$3,500+

Fuel/Energy:

- Electric forklifts: Lower cost per hour of operation. Charging costs may run $1-$2 per full cycle, but battery replacements every 3-5 years can cost $2,000-$5,000.

- Propane forklifts: Average $3-$5 per hour in fuel depending on usage intensity.

- Diesel forklifts: Typically cost $4-$6 per hour and may incur environmental compliance costs.

Other operating costs:

- Insurance: Basic coverage ranges from $500-$1,200 annually. High-risk industries or full coverage plans may range from $1,500-$2,500+.

- Licensing and compliance: OSHA certification for operators may cost $150-$300 per person. Some jurisdictions require registration or inspections.

- Operator training: Initial training costs $200-$500 per employee, and recertification every 3 years may cost $100-$300.

Price Influencing Factors

Whether you’re considering a used forklift or a brand-new one, several variables impact cost:

- Forklift size and load capacity: Larger forklifts with higher capacity cost more due to stronger frames and components.

- Power type (electric vs. gas vs. diesel): Electric models are efficient but need chargers; gas/diesel have lower upfront cost but higher fuel expense.

- Brand reputation: Well-known brands often cost more but offer better resale value and parts support.

- Dealer location and shipping fees: Proximity impacts delivery cost and service speed.

- Financing options: Flexible financing can reduce upfront costs but may affect long-term ownership expenses.

Each of these plays a role in your final investment and should be weighed accordingly.

What You Save: Financial Benefits of Buying Used

Buying a used forklift provides cost savings and long-term financial flexibility.

Lower Initial Investment

Choosing a used forklift reduces your initial capital outlay. This frees up money for other needs-whether it’s hiring staff, purchasing inventory, or expanding operations.

Especially for companies managing tight budgets, the cost of used forklift equipment creates breathing room while still delivering reliable performance.

Faster Return on Investment (ROI)

With a smaller initial cost, your return on investment accelerates. Many companies find that used equipment pays for itself within months, particularly in light-duty or seasonal environments. A faster ROI allows reinvestment sooner into additional assets or upgrades.

Avoiding Rapid Depreciation

A new forklift loses a significant portion of its value the moment it’s delivered, often 20-25% in the first year. A used forklift has already gone through that stage of depreciation.

This stability in value makes used machines a smart investment, particularly if you plan to resell within a few years.

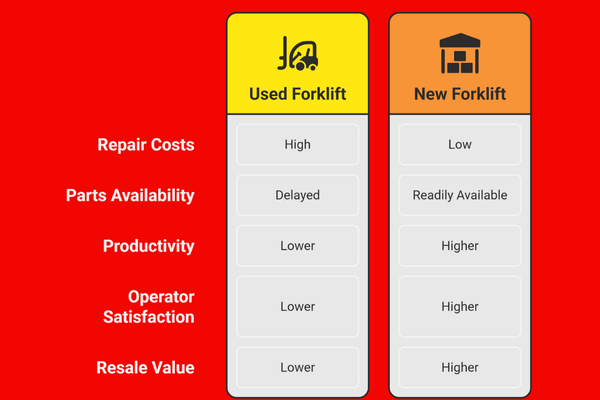

What You Risk: Downsides of Used Forklifts

Used forklifts come with several operational and financial risks to keep in mind.

- Higher Maintenance Costs: Older components require more frequent repairs, increasing the total forklift maintenance cost.

- Unknown History: Without service records, it’s hard to know how well a used forklift was maintained.

- Shorter Lifespan: Many used forklifts have already logged thousands of hours, leaving limited usage time.

- No Warranty: Most used units have limited or no coverage, exposing you to early repair costs.

- Outdated Safety Features: Older forklifts may lack modern safety tech like backup cameras or emission controls.

- Downtime Risk: A used forklift is more likely to break down, interrupting workflow and productivity.

Key Considerations for Your Operation

Your forklift choice should align with your business’s operational requirements.

Intended Use and Frequency

If you’re using forklifts daily in high-demand environments, the reliability of a new forklift may be essential. For occasional or light use, a used forklift often meets the need.

The more critical the role, the more it makes sense to avoid the forklift maintenance cost and downtime associated with older equipment.

Resale Value Planning

If you intend to resell in 2-3 years, a new forklift may retain value better-especially with regular maintenance. Buying used avoids early depreciation, so resale loss may be lower in actual dollars. Forklift resale value depends on usage, maintenance, and market demand.

Parts Availability

Before you buy used forklift models, research parts availability; older machines may have discontinued components, resulting in repair delays and higher costs. Brands with strong dealer support are safer bets for used purchases.

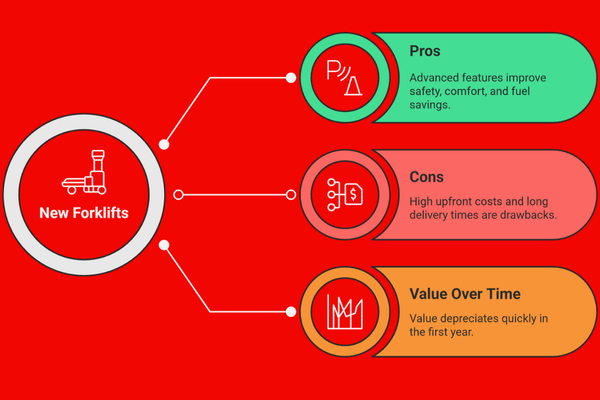

New Forklifts: Pros, Cons, and Value Over Time

New forklifts offer several advantages that improve long-term performance and reliability.

Pros of Buying New

- Advanced features improve safety, comfort, and fuel savings.

- Warranty covers parts and repairs, reducing early expenses.

- New forklifts can be tailored to match your operational needs.

- Fewer repairs lower long-term forklift maintenance costs.

- Dealers provide training and support to improve usage.

These benefits can justify the higher new forklift cost for high-use operations.

Cons of Buying New

- High upfront expense: New forklifts require significant initial capital.

- Long lead times for delivery: Ordering a new unit may delay operations.

- Steep first-year forklift depreciation: Value drops quickly in the first year.

For businesses with limited capital or urgent equipment needs, these drawbacks may outweigh the pros.

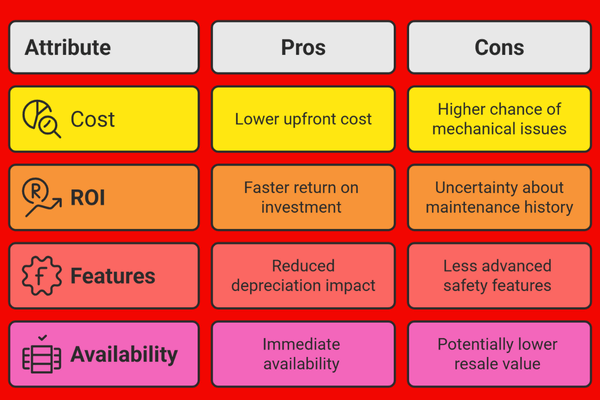

Used Forklifts: Pros, Cons, and Buying Considerations

Used equipment offers a balance of affordability and functionality.

Pros of Buying Used

- Lower cost of used forklift options: Used forklifts are more affordable upfront.

- Faster ROI: Lower investment leads to quicker cost recovery.

- Reduced depreciation impact: Most depreciation has already occurred.

- Immediate availability from dealers or auctions: Units are ready for quick deployment.

These benefits make buying a used forklift appealing for small businesses and growing operations.

Cons of Buying Used

- Higher chance of mechanical issues: Older forklifts may need frequent repairs due to worn parts.

- Uncertainty about maintenance history: Without service records, it’s hard to assess previous care.

- Less advanced safety features: Used forklifts may lack modern tech like cameras or warning systems.

- Potentially lower forklift resale value: Older models typically sell for less on the secondary market.

The best way to reduce these risks is through thorough inspection and working with a reputable seller.

Hidden Costs and Long-Term Impacts

Ownership includes expenses beyond the purchase price. These should inform your decision.

Hidden Costs of Used Forklifts

- Emergency repair bills: Sudden breakdowns lead to unexpected, high repair costs.

- Delay in finding rare parts: Older forklift parts can be hard to source, delaying repairs.

- Productivity losses from downtime: Equipment failure interrupts operations and reduces output.

Even a lower-cost used forklift can become expensive if issues are frequent.

Long-Term Value of New Forklifts

- Reliable performance for longer: New forklifts operate efficiently for more hours.

- Lower repair frequency: Fewer breakdowns mean lower ongoing maintenance needs.

- Higher operator satisfaction: Improved comfort and features boost driver morale.

- Better forklift resale value after 3-5 years: New units retain stronger value over time.

These factors improve the total cost of ownership over time and may justify the initial new forklift cost.

When to Choose New vs. Used Forklift

Use this section to decide which option fits your business case.

Choose New If:

- Your forklifts are used daily in harsh conditions: Daily use in demanding environments requires new, reliable equipment.

- Specific safety features are required: New models include modern safety tech to meet compliance and reduce accidents.

- You’re building a long-term fleet: New forklifts ensure consistency, lower maintenance, and better integration.

- You can afford the upfront new forklift cost: If budget allows, a new purchase offers long-term reliability and value.

Choose Used If:

- You have limited capital: A used forklift fits tight budgets and avoids heavy upfront costs.

- Forklift usage is light or seasonal: Occasional use doesn’t require a brand-new machine.

- You need equipment immediately: Used models are typically ready to deploy right away.

- You can inspect the used forklift and verify its history: Knowing its condition reduces purchase risk.

Tips for Making the Best Decision

A few key actions help avoid costly mistakes.

1. Choose a Reputable Brand

Well-known brands offer stronger aftermarket support, better forklift resale value, and easier access to parts.

2. Work With a Trusted Forklift Dealer

Look for sellers who inspect, refurbish, and provide basic warranties. This is essential when you buy used forklift equipment.

3. Conduct a Full Inspection

Always inspect the forks, tires, mast, hydraulics, and battery. Look for leaks, cracks, or abnormal wear.

4. Request Full Service Records

A documented maintenance history helps predict future forklift maintenance costs and performance.

5. Ask About Warranty Options

Some used forklift dealers offer service plans or extended warranties. Ask what’s available.

6. Calculate Total Ownership Cost

Include insurance, fuel, maintenance, downtime, and forklift depreciation to get a full financial picture.

Frequently Asked Questions (FAQs)

What should I check when buying a used forklift?

Inspect all key components thoroughly before purchase. Check mast movement, tilt cylinders, battery life, tire condition, hour meter accuracy, any fluid leaks, frame integrity, and review maintenance records for service history.

How many hours is good for a used forklift?

Under 8,000 hours is good. Under 5,000 is excellent. Be cautious of anything over 12,000 without strong maintenance documentation.

What is the average forklift lifespan?

Most forklifts last 10,000 to 20,000 hours. Electric models may last longer with battery replacements.

When should you replace a forklift?

If forklift maintenance cost exceeds 60% of the machine’s value or downtime becomes frequent, consider replacing it.

What is the forklift depreciation rate?

Depreciation is usually 20-25% in year one, then about 10-15% annually. For accounting, the typical life is 5-7 years.

Trusted Support and Inventory from Value Forklifts

At Value Forklifts, we help businesses make smart decisions when they buy used forklift equipment. With 30+ years of experience, we know how to match the right machine to your needs.

Our inventory includes over 200 ready-to-work forklifts-electric, propane, stand-up, and narrow aisle-reconditioned and fully serviced.

We provide expert advice, nationwide shipping, and access to trusted brands like Toyota, Cat, and Yale. Working with us means gaining a knowledgeable partner who delivers dependable used forklift solutions tailored to your business.

Conclusion

Choosing the right forklift means evaluating upfront cost, maintenance needs, depreciation, usage frequency, and long-term value. A new forklift provides reliability, warranties, and modern features, while a used forklift offers affordability, quicker ROI, and immediate availability.

Each choice has its own unique benefits and drawbacks, and the ideal decision really depends on your specific operational requirements and financial goals. Use this guide to ensure your forklift investment aligns perfectly with your business priorities.

Need help finding the right forklift? Contact Value Forklifts today. Our experts are ready to match you with a reliable, budget-friendly solution.