What Are the Most Common Problems with Electric Pallet Jacks and How to Fix ThemCopy of Which Forklifts are Best for Heavy Duty Lifting?

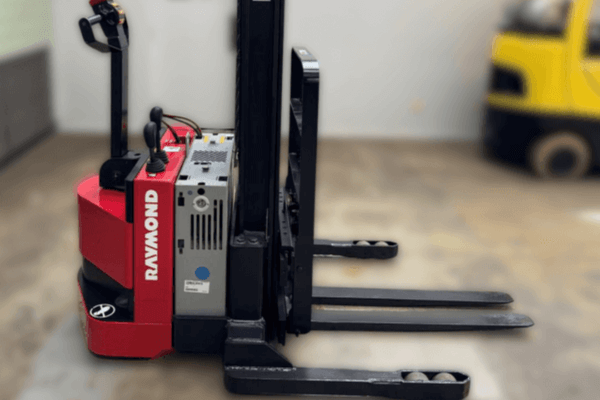

Electric pallet jacks are crucial in warehouses, construction sites, and logistics facilities. They simplify heavy lifting, speed up workflow, and reduce strain on workers. Even the most reliable electric pallet jacks can develop electrical or mechanical problems after long-term use. Learning how to troubleshoot and perform basic pallet jack repair can save time, money, and effort while extending the life of your machine.

Understanding the Basics of Electric Pallet Jacks

Before diagnosing problems, it helps to know how electric pallet jacks function. Familiarity with their systems and operation allows operators to identify issues early and perform basic electric pallet jack troubleshooting safely and effectively.

Key Components

Every electric pallet jack relies on a few critical systems that work together to perform efficiently:

- Battery and Charger System: Supplies power to the motor and controls. A properly maintained battery ensures smooth operation and consistent performance.

- Hydraulic Lift System: Uses pressurized fluid to raise and lower loads safely.

- Drive Motor and Gearbox: Converts electrical power into movement, allowing the pallet jack to travel across floors.

- Control Handle and Wiring: Provides the operator with control over direction, speed, and lift functions.

Why Knowing the Basics Helps

Understanding how these systems function allows for better equipment care and problem-solving:

- Faster Problem Detection: Knowing how each part functions helps you catch problems early. Quick diagnosis reduces downtime and limits repair costs.

- Lower Maintenance Costs: Operators familiar with their equipment can perform small fixes on-site, avoiding unnecessary professional service calls.

- Better Operator Safety: Understanding how electric pallet jacks respond under different conditions builds confidence and reduces the risk of accidents.

Common Problems with Electric Pallet Jacks (and How to Fix Them)

Even durable pallet jacks can develop performance problems over time. Recognizing symptoms early helps users perform effective electric pallet jack troubleshooting and extend equipment life.

Battery and Electrical Issues

Power loss, slow operation, or failure to start often indicate battery or electrical problems in electric pallet jacks.

Solutions:

- Charge the battery properly: Follow manufacturer instructions for a full charge cycle to restore performance. Avoid overcharging or running the battery too low, as this shortens its lifespan.

- Clean Corroded Terminals: Dirt or corrosion on battery terminals blocks current flow. To clean your terminals, mix baking soda with water, then make sure to dry them thoroughly before reconnecting.

- Repair Damaged Wiring: Look for cracked or frayed cables. Damaged wiring can cause short circuits or voltage drops, so replacing faulty connections keeps the electrical system stable.

- Perform a Battery Reset: Disconnect the battery for a few minutes, then reconnect it to refresh the internal electronics. This simple step often restores full power and clears minor system glitches.

Motor and Mechanical Issues

Grinding noises, vibration, or reduced speed often indicate wear in the motor or drivetrain.

Solutions:

- Lubricate Moving Components: Apply lubricant to all moving parts. This minimizes friction, extends component life, and prevents overheating.

- Check and Replace Bearings: Examine bearings for rust or looseness. Replacing worn bearings helps maintain motor efficiency and reduces vibration.

- Inspect the Gearbox Thoroughly: Open the gearbox and inspect the gears for debris or damage. Clean old grease, replace it with new lubricant, and install new parts if needed.

- Clean Brushes and Electrical Components: Over time, brushes collect dust and carbon buildup. Cleaning or replacing them improves power transfer and prevents electrical faults.

Hydraulic System Issues

When an electric pallet jack struggles to lift or lower, the issue is often hydraulic. Low fluid, trapped air, or worn seals can reduce performance.

Solutions:

- Bleed Trapped Air: Pump the handle 15–20 times to remove air from the hydraulic lines. This restores steady pressure and smoother operation.

- Secure Lift Chains and Fittings: Tighten or replace loose chains or fittings. Proper tension helps maintain balance and consistent lifting.

- Maintain Hydraulic Fluid Levels: Check the fluid reservoir and refill with manufacturer-approved oil. Clean, sufficient fluid ensures stable lift control.

- Inspect Hoses and Seals Thoroughly: Look for cracks, leaks, or discoloration. Replacing worn components prevents fluid loss and protects system integrity.

Wheel and Steering Issues

Difficulty steering or uneven movement often points to wheel wear or misalignment.

Solutions:

- Inspect Drive and Load Wheels: Check for cracks or flat spots. Replacing damaged wheels improves traction and makes handling smoother.

- Remove Debris Around Wheels: Clear any debris caught under the wheels. Even small particles can affect rolling efficiency and increase strain on the motor.

- Realign or Replace Misaligned Wheels: Poor alignment leads to wobbling or uneven steering. Realigning or replacing the wheels restores balance and control.

- Replace Damaged Steering Handles: A damaged or bent handle limits precision. Replacing it restores smooth steering and improves operator comfort.

Electric Pallet Jack Troubleshooting Steps

A structured approach helps identify and fix problems efficiently. If you're looking to diagnose and fix your electric pallet jack, these steps can help you out.

Step 1 – Conduct a Visual Inspection

Look for obvious damage such as leaks, loose wires, or worn parts. Check the wheels, hydraulics, and cables for visible signs of wear or obstruction.

Step 2 – Test Battery and Electrical Functions

Use a voltmeter to measure the battery's charge. If the reading is on the low side, you should either recharge it or get a new battery. Examine connectors to verify that electrical flow is consistent.

Step 3 – Examine Hydraulic Components

Inspect hydraulic seals and hoses for leaks or discoloration. Replacing damaged parts early prevents further system strain.

Step 4 – Test Drive and Lift Functions

Operate the pallet jack under a light load. Listen for unusual sounds or sluggish movement. Any hesitation or vibration could signal deeper electrical or mechanical issues.

Step 5 – When to Call for Professional Pallet Jack Repair

For complex problems involving motors, hydraulics, or electrical wiring, contact a certified technician. Professional service prevents long-term damage and improves safety.

Preventative Maintenance Tips

Consistent care keeps electric pallet jacks operating efficiently while avoiding expensive breakdowns. A clear maintenance plan promotes safety and long-term reliability.

Daily and Weekly Maintenance

- Check Battery Water Levels and Terminals: Monitor battery water levels and refill with distilled water as needed. Clean corroded terminals with a mild solution and a brush to maintain solid electrical contact.

- Inspect Tires for Wear and Inflation: Check tires for cracks or uneven wear. Correct pressure ensures smooth motion and minimizes stress on drive components.

- Clean Handles, Controls, and Surfaces: Wipe all contact surfaces to remove dust and grease. Clean controls enhance comfort, safety, and hygiene for daily operators.

Monthly and Quarterly Maintenance

- Inspect and Lubricate Hydraulic Components: Look for leaks or worn parts in pumps and cylinders. Add lubrication to reduce friction and preserve smooth movement.

- Maintain a Detailed Maintenance Log: Record dates and tasks for every maintenance session. Documentation helps with warranty validation and identifies performance patterns.

- Test the Charger and Electrical System: Check the charger for proper function and inspect all cables. Reliable charging extends battery life and keeps the jack ready for use.

Operator Training

Training reduces misuse and promotes safer handling. OSHA-approved instruction gives operators the knowledge to manage electric pallet jacks responsibly. Skilled users recognize early warning signs and take action before damage occurs.

When It's Time to Replace or Trade In Your Pallet Jack

Even well-maintained equipment eventually reaches a point where replacement is more practical than repair. Recognizing that point saves both time and money.

Repair vs. Replace – Knowing the Right Time

Frequent malfunctions or high repair bills indicate it's time for a replacement. Compare ongoing repair costs with the price of a new or reconditioned model. If repairs approach half the replacement cost, investing in newer equipment makes better financial sense.

Benefits of Reconditioned Equipment

Reconditioned electric pallet jacks and forklifts provide durability and value. Each unit undergoes inspection, repair, and testing before being resold.

Advantages:

- Lower Initial Investment: Refurbished pallet jacks offer quality performance at a lower price, helping companies expand fleets while staying within budget.

- Warranty Coverage: Every reconditioned unit comes with warranty protection that builds confidence in its performance and dependability.

- Nationwide Availability: Value Forklifts provides reconditioned pallet jacks across the country with prompt delivery and responsive customer support.

Trade-In and Resale Opportunities

Trading in used pallet jacks or forklifts is a smart way to upgrade while recouping value. Partnering with reliable dealers guarantees fair assessments and streamlined transactions.

Value Forklifts – Your Partner in Reliable Used Equipment

Selecting the right supplier matters when it comes to purchasing or repairing electric pallet jacks. Value Forklifts provides expert service, dependable products, and nationwide delivery.

Our Mission and Experience

For over 30 years, Value Forklifts has supported companies with affordable, top-quality used forklifts and pallet jacks. Our goal is to help facility managers move materials efficiently while maintaining cost control.

We focus on matching every client with the ideal electric pallet jack or forklift for their operational needs.

Our Offerings – Used Forklifts, New Quality

Value Forklifts carries trusted brands such as Toyota, Yale, Cat, and Hyster. Each used forklift is inspected, serviced, and restored to dependable working condition, complete with new paint and tires.

With more than 200 units available for delivery nationwide, finding a reliable electric pallet jack is quick and convenient.

Used Forklifts – Like New at Used Prices

Our reconditioned inventory delivers strong performance without the premium price tag. Whether you need propane, electric, narrow aisle, or reach trucks, we have the right fit for your operation.

Explore our range of reconditioned pallet jacks and discover how Value Forklifts can help improve your material-handling process.

Conclusion

Common pallet jack problems can be managed with proactive care and early intervention. Understanding how each system operates allows operators to identify faults quickly and maintain consistent performance from their electric pallet jacks.

For advanced repairs or equipment upgrades, choose reconditioned pallet jacks from Value Forklifts. The company's reliable machines and knowledgeable staff support safe, efficient, and cost-effective operations.

Looking to upgrade your material-handling fleet? Visit Value Forklifts to explore a complete range of reconditioned electric pallet jacks and forklifts designed for durability and performance.

Contact Value Forklifts today to speak with an expert and find the best equipment for your facility.

Frequently Asked Questions (FAQs)

Why Is My Electric Pallet Jack Not Lifting?

- Low hydraulic fluid, air in the system, or worn seals often cause lifting problems. Regular electric pallet jack troubleshooting can prevent these issues and keep lifting performance consistent.

How Long Do Electric Pallet Jacks Last?

- A properly maintained electric pallet jack can last between five and ten years. Routine hydraulic and battery care adds years of dependable service.

How Do You Inspect an Electric Pallet Jack?

- Inspect for leaks, loose wiring, and worn parts. Conduct a light-load test to check lift, drive, and steering functions for smooth operation.

Does OSHA Require Certification for Electric Pallet Jacks?

- Yes. OSHA requires all operators of electric pallet jacks to complete certified training. Refresher courses every three years help maintain compliance and workplace safety.