Common Battery Maintenance Mistakes and How They Sabotage Your Forklift Fleet

Your forklift battery is the beating heart of your electric fleet. It's the fuel tank that powers every lift, every shift, and every deadline your operation needs to meet. But here's the uncomfortable truth: this single component is often the most expensive consumable part in your warehouse, and yet it's one of the most neglected.

Depending on size and capacity, the average electric forklift battery may range from $2,000 to $6,000 or more. When well maintained, the batteries are expected to give 1,500 to 2,000 charge cycles, which is equated to five to seven years of usability. However, in case of a maintenance failure? You have early breakdowns, expensive side repairs, unplanned interruptions, and frustrated operators.

This blog will outline the most universal types of forklift battery maintenance errors that cripple operational processes daily and, more to the point, demonstrate how to prevent them. These tips will assist you when dealing with only one forklift or when dealing with a large fleet of forklifts to maintain prolonged battery life and lower expenses, and keep everything running smoothly.

Common Battery Maintenance Mistakes That Are Costing You Money

It is time to dive into the five mistakes that warehouse managers and operators make repeatedly and what you can do differently as of today.

Mistake 1: Opportunity Charging (Short Charging Without the Right Battery)

- The Mistake: It is so convenient, isn't it? During the lunch break, an operator connects the forklift, charges it for 30 minutes, and then continues his work. It is referred to as opportunity charging, and although it sounds efficient, it is a silent battery killer- unless one has a battery that is specific to it.

The majority of the traditional lead-acid industrial batteries are intended to have full and complete charge cycles. You are pushing the limits of the battery when you charge it in short bursts throughout the day.

- The Consequence: There are two issues with short charging sessions. To start with, they cause too much heat. Batteries are electrochemical systems, and untimely, hasty charging becomes internal resistance, which converts to heat. This heat will eventually destroy the internal parts of the battery and cause wear.

Second, each time you charge the battery, whether it is 15 minutes or longer, you are literally consuming a part of your battery life cycle, which is just finite. A 1,500-cycle battery could be burned in half the time when you are charging it every half-hour rather than subjecting it to regular charge cycles.

The Fix: Implement a strict charging protocol. Only charge your forklift battery when it reaches the 20-30% capacity range (usually indicated by a red light or low battery warning). This ensures you're maximizing each cycle and preventing unnecessary heat buildup. If your operation genuinely requires opportunity charging, invest in lithium-ion batteries that are purpose-built for this charging style.

💡 Pro Tip: It can be a good idea to have a battery management system that monitors the charge cycles and signals operators when it is really time to charge, not when it is convenient.

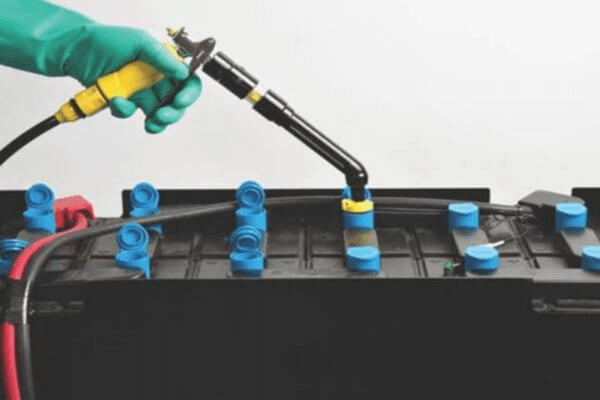

Mistake 2: Improper Watering Practices

- The Mistake: Water is essential for forklift battery care, but timing and water quality matter more than most people realize. Two common errors dominate this category: watering before charging (instead of after), and using tap water instead of distilled water.

Water is lost through electrolysis in the lead-acid batteries, particularly when charging. The water level is increased during the charge cycle when the operators add water before charging, which results in the electrolyte solution overflowing, a phenomenon called “boil-over”.

In the meantime, the tap water brings minerals, calcium, magnesium, and chlorine into the battery. These minerals do not simply dissipate; they build up on the battery plates, forming an obstacle that decreases the capacity of the battery to store and provide a charge.

- The Consequence: Boil-over produces acid spills, which, besides being messy, are also hazardous. Battery acid is corrosive in nature and it may destroy flooring, as well as equipment, and may cause injuries in case of any physical contact. It also implies that you are wasting valuable electrolyte solution keeping your battery running.

Tap water mineral deposits progressively, which diminishes the battery capacity and efficiency. With months and years, this accumulation becomes a handicap that cannot be overcome, decreasing battery life and decreasing the time that can be used between charges.

The Fix: Establish a simple two-part rule for your team:

- Always water after charging is complete, when the battery has cooled down and water levels have stabilized.

- Always use distilled, not tap water, not well water, or filtered water. The distilled water is cheap and commonly found, and it is the only kind that will not add destructive pollutants.

Always have distilled water handy in your charging room and educate all the operators on the correct watering procedures. Consider installing automatic watering systems on larger fleets-they would remove human error and make the level of water the same.

⚠️ Reality Check: Industry research has indicated that about 80% of premature battery failures are caused by improper watering. That is an alarming figure for something so avoidable.

Mistake 3: Deep Discharging (Running Batteries Below 20% Capacity)

- The Mistake: It occurs more frequently than it is expected. An operator will see the battery indicator slowly moving into the red area, yet choose to do an extra pallet or an extra load, and then move to the charging station. And the forklift is still in operation, right?

One of the most harmful habits in forklift batteries safety and maintenance is running a battery with less than 20% capacity, or so-called deep discharging.

- The Consequence: The sulfation is a chemical process that increases dramatically when the lead-acid battery is below the capacity of 20%. On the battery plates, the sulfation of the lead may take place as lead sulfate crystals. These crystals dissolve during charging in normal operation. However, in deep discharge, the crystals are more enlarged and hardened and finally become permanent.

The end effect of this permanent sulfation is that the battery becomes less able to accept and store a charge, and, therefore, the battery has a shorter and shorter runtime. Deep discharging is also a source of excessive heat that plates and destroys separators within the battery. The result? Permanent and irreversible capacity loss.

The Fix: Institute a strict "Red Light Rule" across your operation. When the battery indicator hits red (typically around 20-30% remaining capacity), work stops immediately, and the forklift goes to the charging station. No exceptions.

Make this rule part of your safety culture. Explain to operators that running batteries into the red zone isn't just bad for equipment, it's expensive for the company and ultimately affects everyone's job security when maintenance costs goes out of control.

Mistake 4: Skipping Equalization Charges

- The Mistake: The majority of the operators and even web managers do not understand what an equalization charge is, and this lack of understanding costs them money. An equalization charge is a controlled overcharge that is carried out weekly or monthly (depending on how the battery is used) that balances the cells in a battery and stops acid stratification.

When this is omitted, the batteries will have developed imbalanced cells in which some cells are stronger than others. Moreover, the sulfuric acid in the electrolyte solution is deposited on the bottom of the battery (stratification), which forms an uneven level of concentration that decreases performance.

- The Consequence: In the absence of regular equalization, you will observe shorter run times and uneven performance. Certain cells will be fully charged, and others will be behind, i.e., your battery will never use its full potential. Acid stratification also enhances faster corrosion of the bottom plates by sulfation and may lead to corrosion of the upper plates due to the absence of acid contact.

Gradually, these disproportions are critical to the extent that the battery does not last as long as it was designed.

The Fix: Have an equalization of the schedules as one of the normal repairs on the industrial battery maintenance routine. Equalizing all the charge cycles (or at least once a month) is suggested by the majority of manufacturers.

📊 Quick Fact: Batteries that receive regular equalization charges can last 20-30% longer than those that don't. That's an extra year or two of service from the same battery.

Mistake 5: Ignoring Corrosion and Cleanliness

- The Mistake: Go into any warehouse, and you will see at a glance that white or blue-green “fuzz” is depositing itself on battery terminals and connectors. It does not appear dangerous, not even something you could neglect when you are in a hurry. That gray stuff, though, that furry formation, is rust, and it is stealing electricity and posing safety risks.

Corrosion happens when vapors of battery acids interact with metal surfaces of the terminals, forming a non-conducting crusty layer. Most operators do not even know this is an issue; others believe it is normal wear and tear.

- The Consequence: Corrosion forms electrical resistance, and that is to say that your battery will be required to work more to produce the same power. This opposition produces heat, energy wastage, and decreased run time. In extreme situations, corrosion may lead to leakage of voltages and self-discharge, that is, your battery will be losing charge even when it is not being used.

In terms of forklift battery safety, corrosion may also cause arcing or sparking during connections, posing a fire hazard, particularly in areas where flammable substances are involved.

The Fix: Incorporate battery cleaning into your maintenance routine- every month or more often in extreme conditions. Here's how to do it properly:

- Take off the battery and put on the right PPE (gloves, safety glasses, protective clothing).

- Wipe the terminals and connectors with a solution of baking soda and water (a natural acid neutralizer).

- Using a wire brush, scrub the stain thoroughly to remove all the corrosion.

- Rinse with distilled water and dry thoroughly.

How Battery Mistakes Sabotage Your Entire Forklift Fleet

This is what the majority of the population does not know: battery issues do not remain in a vacuum. The failure of one battery will cause a domino effect that will affect your whole operation.

To start with, there is the apparent replacement cost. However, more than that, you have to deal with unplanned downtime as you await a replacement battery to be delivered. Operators are either idled or forced to share equipment, hence reducing productivity on the board. Due dates are missed, clients become angry, and you lose some reputation.

And then there is the expense of collaborating with damaged batteries that is not apparent. Without proper maintenance, the batteries provide haphazard power. The forklifts have reduced speed, the lifting capacities are lower, and the operators are forced to work more in order to complete the same work. This ineffectiveness builds up over weeks and months and slowly swallows up your bottom line.

The good news? All these issues can be avoided by appropriate forklift battery care and adherence to the best practices in maintenance.

Why Choose Value Forklifts for Extending Battery Life

At Value Forklifts, we understand that your electric forklift batteries are a significant investment, and we're committed to helping you protect that investment. Our experience of 30+years working in the industry and having over 400 satisfied customers throughout the country means we have encountered all the battery-related problems one can possibly imagine, and we know all the ways to avoid them.

We offer a complete range of industrial battery solutions, from high-quality replacement batteries to advanced chargers with built-in equalization features. We also carry batteries and chargers for all major forklift brands, including Toyota, Hyster, Yale, Crown, and many others. We also sell used batteries, which can come in handy when you have downtime in battery replacement.

Conclusion: Maintenance Equals Money Saved

Simple math implies that the forklift battery maintenance has a direct relation to the longer battery life, decreased cost of replacement, less downtime, and a safer operation. The errors, which we have discussed, such as short charging, improper watering, deep discharging, failure to pay care to equalization, and negligence on corrosion, are totally avoidable with the proper knowledge and will.

Ready to extend your battery life and reduce costs? Contact us today for expert advice on battery replacements, chargers, or comprehensive maintenance solutions.