Forklift Battery and Charger Safety Requirements Most Facilities Miss

Warehouses move fast, and so do the hidden risks around high-capacity batteries. Small oversights during forklift battery charging or routine checks can trigger costly downtime, fire hazards, or injuries. Strong programs start with consistent procedures, clear responsibilities, and equipment that is matched to the job. When teams prioritize forklift charger safety and disciplined routines, operations stabilize. That means reliable uptime, safer people, and better returns on fleet investments. Whether you run a single site or a multi-location network, the right habits around your forklift battery maintenance practices and the forklift charger bay make a measurable difference. Create a standard, audit it, then keep improving the forklift battery and charger program as the business evolves.

1. Critical Charging Area Requirements Most Facilities Miss

Charging rooms exist across many facilities, yet details that matter are often incomplete. This section covers environmental protections and emergency resources that safeguard people, equipment, and the forklift battery and charger area, elevating forklift charger safety.

Ventilation Designed for Hydrogen Gas Dissipation

Lead-acid units release hydrogen during forklift battery charging, and general warehouse airflow rarely meets the need. Localized exhaust, interlocked fans, or demand-controlled ventilation reduce concentration near parked lift trucks. Audible and visual alarms improve forklift charger safety when paired with hydrogen sensors tied to automatic controls. By managing vented gases at the source, you cut ignition risk without over-ventilating the facility.

Fire Protection Beyond a Basic Extinguisher

The right extinguisher is critical around energized equipment and battery chemistries. Class C units support incidents involving the forklift charger, wiring, and control cabinets. Class D units support metal fires related to certain chemistries and specialized tasks. Clear labeling, recurring inspections, and training close the loop on forklift charger safety during emergencies.

Emergency Equipment Placement and Maintenance

Remember, eyewash stations and safety showers ought to be within a quick walk of the charging bay, not placed all the way across the building. That proximity supports prompt response during forklift battery maintenance involving acid exposure or splashes. Keep paths to stations open at all times, and test the flow regularly so units are ready when needed near the forklift charger work zone.

Spill Containment and Neutralization Readiness

Acid-resistant floors help, yet they do not replace containment and neutralization kits. Stock dedicated supplies for acid spills so people can find them quickly, then train the team on proper PPE and cleanup procedures. Keep kits visible in the forklift battery and charger area and refresh supplies during scheduled forklift battery maintenance cycles.

2. Operator Procedures & Training Gaps That Increase Risk

Infrastructure does its part, but habits determine outcomes. These common errors during forklift battery maintenance and forklift battery charging raise incident rates and damage expensive assets.

Removing Metallic Jewelry Before Handling Batteries

Rings, necklaces, and watches can bridge terminals and create arcs in a split second. Consistent pre-work checks reduce exposure during forklift battery maintenance, especially when teams rotate across shifts. A posted reminder near the bay reinforces the rule and supports forklift charger safety during busy hours.

Full PPE Compliance Throughout the Entire Process

PPE habits often drop during inspections or connector checks, when splashes and contact injuries occur. Maintain face shields, chemical aprons, goggles, and rubber gloves from the first step to the last for any forklift battery maintenance task. This discipline protects the forklift battery and charger area, reduces near-misses, and builds a culture of care.

Verifying Charger and Battery Compatibility

Never "plug and hope." Confirm voltage, amp-hour rating, and connector type before engaging the forklift charger. Mismatches raise temperatures, speed outgassing, and can warp plates, which undercuts forklift charger safety. A quick compatibility checklist posted at each bay ensures the correct pairing of the forklift battery and charger every time.

- Confirm voltage and AH rating against the placard

- Check connector style, cable condition, and polarity

- Verify the charge profile is correct for the chemistry

Keeping Battery Covers Open During Charging

Heat has to go somewhere during forklift battery charging, and closed lids trap it near vulnerable components. Propped covers improve airflow and protect case integrity around the forklift charger stands. Add a visual cue on the truck, like a "charging, covers open" tag, so anyone can spot compliance at a glance.

3. Maintenance Issues and Equipment Oversights

Preventive work loses value when logs are thin or shortcuts become routine. A steady cadence of inspections keeps the forklift battery and charger assets stable and improves outcomes for forklift battery maintenance programs.

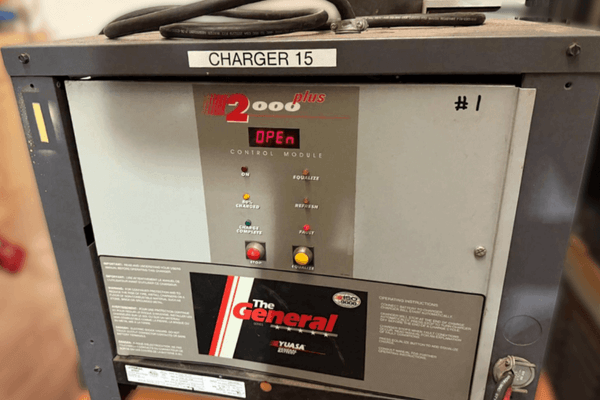

Testing Automatic Shut-off and Smart Charger Functions

Outdated units lacking temperature feedback or reliable termination profiles overcharge and age cells prematurely. A modern forklift charger with microprocessor controls improves energy efficiency and stabilizes forklift battery charging. Routine functional testing tightens forklift charger safety and reduces nuisance alarms, heat, and venting events.

Regular Inspection of Cables, Connectors, and Plugs

Heat marks, corrosion, and cracked insulation lead to intermittent faults that are hard to diagnose. Add terminal cleaning and torque checks to your forklift battery maintenance plan and log replacements by serial number. Visible issues near the forklift battery and charger bay should trigger immediate removal from service.

Using Only Insulated Tools for Battery Work

Bare tools can bridge circuits and damage trays or cells within seconds. Stock insulated hand tools where work occurs, and keep a dedicated kit for forklift battery maintenance activities. This small upgrade supports forklift charger safety while reducing accidental shorts during testing or tightening.

4. OSHA Requirements: Many Facilities Fail to Fully Meet

Regulations specify clear steps for charging, handling, and safety communication. Meeting these expectations protects the forklift battery and charger area, strengthens forklift battery charging protocols, and elevates forklift charger safety during audits and daily use.

Signage, Hazard Labels, and Visible Safety Instructions

Place simple, durable placards that cover voltage, PPE, eyewash locations, and emergency contacts. These visual cues raise awareness and set a shared baseline for forklift charger safety across shifts. Keep labels legible in the forklift battery and charger zone, and replace any that fade or peel.

Correct Battery Handling Equipment

Large batteries require hoists, cranes, or lifting beams sized for the load. This protects spines, fingers, and equipment during forklift battery maintenance involving change-outs or tray pulls. Rated gear and trained operators keep lift lines orderly and reduce equipment strain.

Documented Emergency Response Training

Write the plan, train the team, and keep a record. Drills for eyewash use, spill response, and hydrogen alerts reinforce forklift charger safety when seconds matter. Update the roster as roles change so new hires can quickly find their responsibilities.

5. Operational Practices That Accelerate Battery Damage

Small daily choices add up fast. The following habits undermine forklift battery maintenance plans and destabilize long-term forklift battery charging results.

Improper Opportunity Charging

"Top-ups" without a plan create uneven sulfation and inconsistent shift coverage. Adopt guardrails for forklift battery charging, then log usage by truck to see what actually happens. Calibrated rules help the forklift charger fleet keep pace with demand without shortening service life.

Allowing Batteries to Sit Discharged

Low state-of-charge speeds sulfation and reduces available runtime. Build a fast-turn workflow, so batteries return to forklift battery charging soon after a shift. That cadence supports forklift battery maintenance goals and prevents deep cycling that ages cells.

Lack of Cycle Tracking and Battery Rotation

Without logs, some assets are overworked while others idle for days. Track cycles and rotate units so wear is even across the fleet, and the forklift battery and charger group lasts longer. Data-backed scheduling reduces surprise failures and keeps shift coverage predictable.

6. How Reconditioned Forklifts Help Improve Battery & Charger Safety

Upgraded equipment solves many nagging problems at once. Reconditioned units with verified pairings reduce errors, stabilize performance, and raise forklift charger safety while aligning the forklift battery and charger combination with site demands and the right forklift charger type.

Properly Matched and Tested Battery-Charger Combinations

Compatibility testing prevents mismatches that cook cells, trip breakers, or damage connectors. A reconditioned truck arrives with a paired forklift battery and charger, plus documentation that confirms settings on the forklift charger. That upfront validation cuts troubleshooting time and lifts first-shift reliability.

Removing Hidden Safety Risks in Aging Chargers

Old electronics drift out of spec, fans get weak, and cables harden, which invites failures. Refreshed units and updated controls tighten forklift charger safety by delivering consistent current and reliable termination. When the forklift charger runs cooler and cleaner, batteries last longer, and techs spend less time chasing strange symptoms.

Trade-In Options for Facilities with Outdated Charging Equipment

A planned replacement cycle helps convert aging assets into credit toward reliable units. Upgrading the forklift charger lineup and right-sizing the forklift battery and charger pool streamlines maintenance and cuts energy waste. With the right partners, swaps are quick, and downtime stays minimal.

How We Support Safer, More Cost-Efficient Battery & Charger Operations at Value Forklifts

Value Forklifts focuses on reliable gear, verified pairings, and clear guidance. Our approach connects the right forklift battery and charger with fleet demands, supports forklift charger safety, and strengthens programs built on consistent forklift battery maintenance and a robust forklift charger plan.

We Provide Correctly Paired Batteries and Chargers

We deliver every truck with a verified forklift battery and charger combination that matches voltage, amp-hour rating, connector style, and charge profile. Our technicians validate settings on the forklift charger and document the pairing so operators can plug in with confidence. We also provide simple compatibility checklists that keep shifts consistent and downtime low.

We Recondition Equipment With Safety and Longevity in Mind

We rebuild forklifts with careful attention to wiring, connectors, cooling paths, and trays to support safe forklift battery maintenance. Our process includes cable replacements, terminal cleaning, and functional tests that reduce heat, arcing, and nuisance faults at the charger bay. We finish with clear labeling and practical guidance that helps your team follow best practices.

We Help Clients Minimize Total Cost of Ownership

We combine reliable equipment, practical training, and straightforward documentation to cut hidden costs. Our approach balances a modern forklift charger lineup with disciplined forklift battery charging routines so fleets last longer and run steadier. We back it with responsive support, parts availability, and shipping options that keep projects on schedule.

Conclusion

Accidents and early battery failures often trace back to small oversights that repeat day after day. Tighter habits around ventilation, PPE, spill response, and inspections safeguard people, stabilize forklift battery charging, and keep programs aligned with forklift battery maintenance goals. With the right gear in place, the forklift battery and charger fleet runs cooler, cleaner, and more predictably, especially when each forklift charger is correctly matched and maintained. A culture that values forklift charger safety pays off in uptime, fewer injuries, and a healthier bottom line.

Ready to upgrade confidence in your charging bays and trucks? Contact Value Forklifts for expert guidance, reliable reconditioned units, and properly paired forklift battery and charger solutions that fit your site. Talk to our team to streamline forklift battery charging and reinforce safety standards across your operation.