How Do You Know When It’s Time to Retire or Trade in Your Forklift?

Forklifts are the backbone of warehouse, logistics, and construction operations, keeping materials moving efficiently and safely. Like any piece of equipment, forklifts wear down over time, creating risks of downtime, costly repairs, and safety hazards. Recognizing when it's time for forklift replacement or considering trade-in options can save money, protect workers, and keep operations running smoothly. This article explores practical indicators, cost-value considerations, and maintenance strategies to help you make the best decision for your fleet.

Key Indicators That It's Time to Retire or Trade In Your Forklift

A forklift does not suddenly fail without warning. It often shows signs that its useful years are ending. Spotting these signals helps businesses prepare for forklift replacement or trade-in opportunities. They usually appear in performance, safety, or overall reliability.

Frequent Breakdowns and Rising Maintenance Costs

If your forklift ends up in the shop repeatedly, repair bills can soon rival the cost of a newer machine. Keeping records of repair history highlights patterns, and if breakdowns happen monthly, forklift maintenance alone is no longer enough. At this point, planning a forklift replacement makes better financial sense, especially as older parts become harder to find.

Declining Performance and Productivity

When a forklift struggles with speed, load handling, or maneuverability, efficiency takes a hit. Reduced lift capacity or slower cycles lead to lost work hours and higher costs. If operators spend more time on basic tasks, the forklift's lifespan is nearing its end. Using a forklift checklist during inspections confirms whether performance is slipping beyond recovery.

Safety Concerns and Malfunctioning Equipment

Safety cannot be compromised. Jerking motions, hydraulic leaks, mast failures, or outdated safety systems put operators and materials at risk. Routine forklift safety inspections and daily forklift safety checks may reveal issues that cannot be reliably fixed. Once safety risks outweigh repair costs, retiring the forklift is the responsible choice.

Operating Hours and Age Guidelines

Most forklifts are designed to last about 10,000 hours or seven to eight years. In high-use environments such as distribution centers, the forklift lifespan can be shortened. As the machine approaches these limits, review forklift depreciation and decide if further repairs are wise, or if a planned forklift replacement is a safer option.

Cost & Value Factors to Consider

The decision to repair, replace, or trade in a forklift involves weighing cost against value. Careful evaluation ensures resources are used wisely and long-term productivity is protected.

Rising Maintenance Costs

When ongoing forklift maintenance costs rise steadily, compare total repair spending with the price of a newer model. Downtime combined with frequent repair bills often costs more than investing in a dependable forklift replacement. Considering forklift depreciation provides a fuller financial perspective.

Lower Resale Value and Trade-In Considerations

A forklift's resale value drops once it exceeds 10,000 hours. Trading in sooner can help recover a larger portion of the machine's value. Businesses looking to sell forklifts should keep detailed service records, as these improve trade-in offers and demonstrate responsible care.

Cost-Benefit Analysis of Replacement

A cost-benefit review weighs the expense of downtime, repair bills, and efficiency loss against the price of a new or reconditioned forklift. Often, buying a used forklift offers balance, combining affordability with reliability while minimizing operational interruptions.

When to Completely Retire a Forklift

Some forklifts reach a point where further repair or trade-in is no longer practical. In these cases, full retirement is the best choice.

Safety Risks Outweigh Repair Costs

When safety systems fail repeatedly despite regular forklift maintenance, risk levels climb too high. Problems like mast failures, leaking hydraulics, or weak brakes mean the forklift is no longer safe, regardless of past investment.

Excessive Downtime

If a forklift spends more time under repair than in service, workflows suffer. Persistent downtime disrupts schedules, and forklift replacement becomes the only realistic solution to restore reliability.

Declining Operational Efficiency

Even when repairs are possible, performance may never return to required levels. If efficiency falls steadily, extending the forklift lifespan is unrealistic. Retiring the forklift avoids ongoing losses and allows investment in a stronger replacement.

When to Trade In Your Old Forklift

For machines that remain in fair condition, trade-in programs can deliver strong value. Rather than scrapping, trade-ins help offset the cost of new or reconditioned units.

Achieving a Fair Market Value

Complete forklift maintenance records, lower usage hours, and good condition raise forklift resale value. Trade-in programs reward businesses that maintain their fleets well, making it easier to sell forklifts at a fair price.

Streamlining Fleet Upgrades

Trade-ins simplify upgrading your fleet while managing costs. Offsetting expenses with older equipment allows you to add used forklifts or newer models and keep operations running without strain on budgets.

Nationwide Availability and Trusted Service

Established dealers offer nationwide trade-in programs with warranty-backed machines. Partnering with trusted providers allows businesses to sell forklifts with confidence and secure reliable replacements.

Buying Used or Reconditioned Forklifts

For businesses that want to strike a balance between cost and reliability, opting for a used forklift can be a smart choice. Reconditioned units extend service life while remaining budget-friendly compared to new machines.

Key Checks Before Buying

Always inspect carefully using a forklift checklist. Ensure brakes, hydraulics, tires, and the mast function correctly. A thorough forklift safety inspection reduces the chance of unexpected failures after purchase.

Evaluating Depreciation and Lifespan

Any used forklift has already experienced forklift depreciation. Understanding its remaining forklift lifespan is key. Reviewing maintenance records helps gauge reliability and determine if warranty coverage is possible.

Matching Equipment to Operational Needs

Each workplace requires different equipment. Warehouses may benefit from reach trucks, while construction sites need heavy-duty models. Choosing the right used forklift for the environment improves safety, efficiency, and value.

Preventive Maintenance to Extend Forklift Life

Consistent care is vital for extending equipment life and preserving forklift resale value. Routine inspections and prompt servicing maintain safe, efficient operation.

Daily and Monthly Maintenance Checks

Operators should examine brakes, hydraulics, fluids, tires, and the mast regularly. A forklift checklist provides structure for these inspections. Daily and monthly forklift safety checks catch issues before they become expensive breakdowns.

Documentation and Safety Checks

Keeping detailed records of each forklift safety inspection and repair creates accountability and improves resale potential. When businesses decide to sell forklifts, a complete history of care proves valuable to buyers.

Value Forklifts: Your Trusted Partner for Buying and Selling Used Forklifts

At Value Forklifts, we help businesses find the right used forklift to support efficient operations and cost savings. Our team matches equipment to your needs, ensuring you get dependable performance at a fair price.

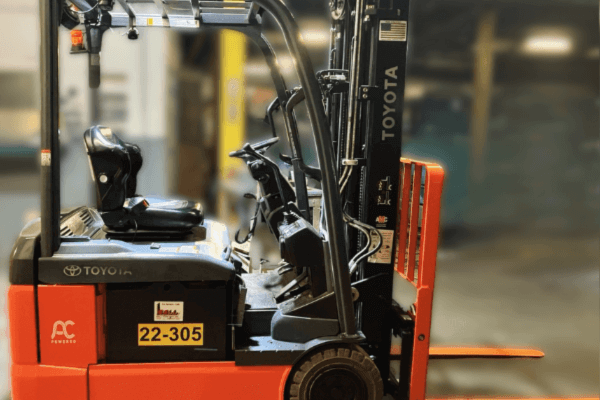

Our inventory features respected brands like Hyster, Yale, Cat, and Toyota, all fully serviced and ready to work. Every forklift is carefully checked so you can trust it from the start.

We recondition equipment with fresh paint, new rubber, and complete forklift safety inspections. These steps deliver machines that look sharp and operate with reliability.

With nationwide shipping and over 200 forklifts listed online, we make it straightforward to buy, trade, or sell equipment. Our process is efficient, helping you avoid unnecessary delays.

With three decades of experience, we provide guidance for every industry setting. Whether in a warehouse or a construction site, our advice helps you choose the forklift that fits best.

Conclusion

This article outlined the most important signals of an aging forklift, from frequent breakdowns and rising repair bills to safety hazards and declining efficiency. It explained how financial considerations, such as forklift depreciation and forklift resale value, guide decisions about trade-in or retirement. It also covered when complete retirement is necessary, how trade-in programs can maximize value, the advantages of buying a used forklift, and the role of preventive forklift maintenance in extending service life. Understanding these factors allows businesses to plan ahead, protect workers, and keep operations productive.

Ready to upgrade? Value Forklifts makes it simple to buy used forklifts, trade in older models, or sell forklifts at fair market value. Contact us today to explore our nationwide inventory and expert guidance.

Common Questions About Retiring or Trading in Your Forklift

What's the average lifespan of a forklift?

- A forklift typically lasts around 10,000 hours or 7–8 years, depending on usage.

How much is a forklift worth for trade-in?

The forklift resale value depends on condition, hours, and maintenance history.

When should you replace a forklift?

- Consider forklift replacement when repairs are frequent, downtime increases, or safety is compromised.

How long is a forklift good for?

- With proper forklift maintenance, many units can operate reliably for 7–10 years.

What to check when buying a used forklift?

- Use a forklift checklist and conduct a forklift safety inspection to confirm condition and reliability.

What is the depreciable life of a forklift?

- The average forklift depreciation period is 7 years, though usage intensity can shorten this timeline.