How to Calculate the True Hourly Cost of Running a Used Forklift

Choosing to buy a used forklift can be a great financial strategy, particularly for businesses that want to reduce their initial spending. The real savings appear when companies understand the true hourly cost of ownership. Beyond the purchase price, expenses like forklift maintenance costs, depreciation, fuel, downtime, and other overheads play a vital role in determining the actual operating cost. By carefully calculating this figure, businesses can make better decisions about whether to buy, lease, or replace equipment.

Why Cost per Hour Matters for Forklift Ownership

Understanding the cost per hour of a forklift provides an accurate measure of operational efficiency. This figure reflects the money spent on acquiring a used forklift along with the ongoing expenses that accumulate through daily use. Many companies assume the lowest purchase price equals the best deal, but ongoing expenses often outweigh initial savings. Taking into account factors like forklift maintenance and fuel gives companies a clearer picture of operating costs.

Better Comparison Between Models

Calculating cost per hour allows businesses to compare forklift models fairly, whether diesel, propane, or electric. A model with higher efficiency or lower repair needs may show a lower long-term used forklift cost, even if the sticker price is slightly higher. This helps organizations make better choices when they decide to buy used forklift equipment.

Smarter Budgeting

When companies track expenses at the hourly level, they can budget more precisely. This makes it easier to forecast future expenses, schedule replacements, and prevent financial surprises related to sudden repairs or inefficiencies. Linking these calculations to actual forklift maintenance schedules provides added accuracy.

Avoiding Hidden Costs

Hidden costs such as insurance, downtime, and inefficient fuel use often go unnoticed. Cost-per-hour calculations ensure these are included, giving a complete picture of the real forklift maintenance cost and total operating expense.

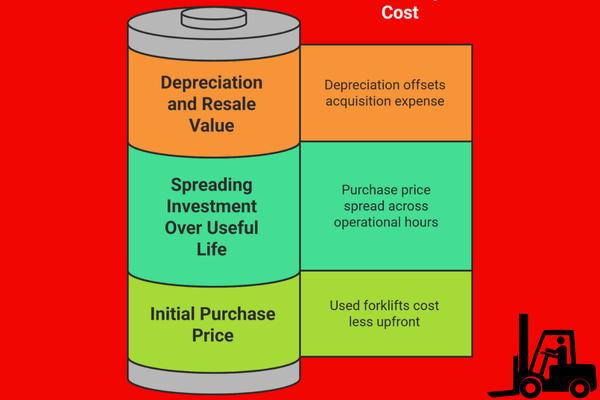

Acquisition & Depreciation Cost

When businesses choose to buy a used forklift, the acquisition price is only part of the equation. Depreciation, or the loss of value over time, significantly affects ownership cost.

Initial Purchase Price

A used forklift costs less upfront compared to new equipment. These initial savings attract many companies, but the machine's condition and expected lifespan must be considered.

Spreading Investment Over Useful Life

The purchase price should be spread across the total hours the forklift will realistically operate. For example, if a used forklift costs $20,000 and it will be used for 10,000 hours, the basic acquisition cost is $2/hour before adding other expenses.

Depreciation and Resale Value

Forklifts depreciate at different rates depending on brand, age, and condition. A well-maintained Toyota or Hyster may hold value better than a neglected unit. Factoring in the depreciation cost helps offset the acquisition expense when considering future resale or trade-in.

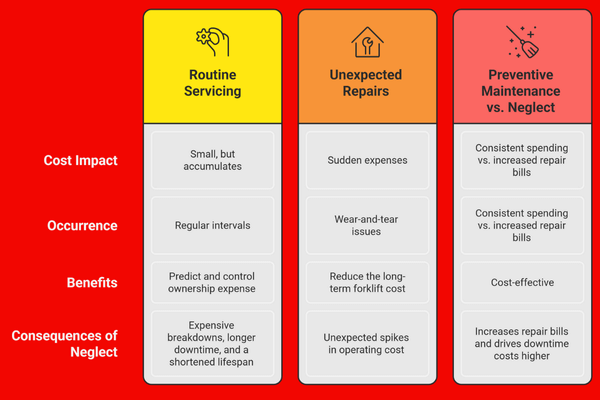

Forklift Maintenance Cost & Repairs

Maintenance is one of the most important factors in calculating hourly cost. Ignoring or delaying maintenance often leads to expensive breakdowns, longer downtime, and a shortened lifespan. Regular tracking of forklift maintenance costs makes it easier to predict and control the ownership expense of a used forklift.

Routine Servicing

Regular servicing includes oil changes, filter replacements, and safety inspections. These costs may appear small, but over hundreds of hours, they form a major part of the total forklift maintenance cost for any used forklift.

Unexpected Repairs

Used forklifts are more likely to face wear-and-tear issues. Transmission problems, hydraulic leaks, or engine failures can lead to sudden expenses. Planning for these repairs avoids unexpected spikes in operating cost and helps reduce the long-term forklift cost.

Preventive Maintenance vs. Neglect

Preventive maintenance requires consistent spending but is more cost-effective than neglect. Neglect increases repair bills and drives downtime costs higher, making forklift maintenance one of the most critical elements in ownership costs.

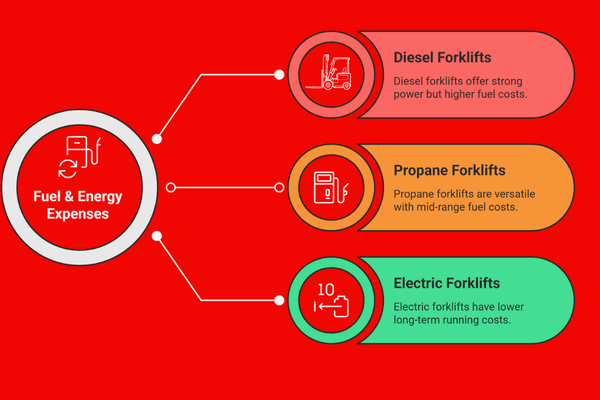

Fuel & Energy Expenses

Fuel is a recurring cost that directly impacts the cost per hour. Whether propane, diesel, or electric, energy costs form a significant part of the overall used forklift cost and should be considered carefully when companies plan to buy used forklift equipment.

Fuel Type Considerations

- Diesel Forklifts: Strong power output but higher fuel expenses, which raise the lifetime used forklift cost.

- Propane Forklifts: Flexible for indoor and outdoor use, mid-range fuel cost, and a common choice when businesses decide to buy used forklift models.

- Electric Forklifts: Higher upfront battery cost but lower long-term running cost, often making them a cost-effective used forklift option.

Average Consumption Per Hour

Each type has unique consumption rates. An electric forklift might cost $1–$2 per hour in electricity, while propane could be $3–$4, and diesel may reach $5–$6 per hour, depending on fuel prices. These differences strongly influence the overall used forklift cost calculation.

Choosing the Right Energy Type

Choosing the right energy source depends on operating conditions, facility layout, and budget priorities. Smart choices here directly reduce hourly expense and support accurate planning when you buy used forklift equipment.

Other Ownership Costs

Fuel and repairs may seem like the biggest expenses, but smaller ownership costs add up quickly and influence the total used forklift cost. Including them in calculations gives a more accurate picture of operating a used forklift.

Insurance and Permits

Insurance premiums and permits are mandatory. Although individually small, they must be included in cost-per-hour calculations to reflect the full cost of forklift maintenance and ownership.

Operator Training and Safety

Proper training reduces accidents and improves efficiency. Investing in training improves safety and reduces hidden costs from damage or misuse, lowering the total used forklift cost over time.

Storage and Equipment

Storage space, safety gear, and specialized tools also form part of expenses. For companies managing multiple used forklifts, these costs can significantly affect the bottom line and overall forklift maintenance planning.

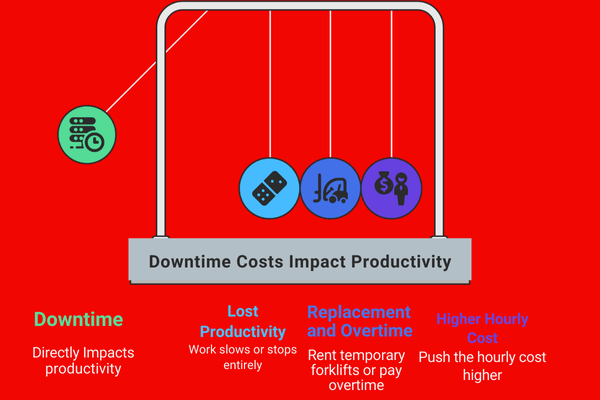

Downtime Costs

Downtime costs often surpass other expenses because they directly impact productivity and add significantly to the overall used forklift cost.

Lost Productivity

Whenever a forklift is out of service, work slows or stops entirely. This creates ripple effects, such as shipment delays and missed deadlines, all of which raise the cost of operating a used forklift.

Replacement and Overtime

Companies often rent temporary forklifts or pay overtime to make up for lost hours. Both add costs beyond the basic used forklift cost and frequently exceed what is budgeted for regular forklift maintenance cost.

Why Downtime Matters Most

Downtime is unpredictable, but it can push the hourly cost higher than any other factor. Businesses must include downtime estimates in their cost-per-hour calculation to avoid underestimation and see the link between forklift maintenance cost and productivity.

Resale Value & End-of-Life Considerations

When a used forklift reaches the end of its useful life, resale or trade-in value becomes important. Factoring this value into calculations reduces the effective used forklift cost per hour.

Estimating Resale Value

Brands known for reliability, like Toyota or Cat, often retain stronger value. Age, service history, and condition heavily influence resale potential for a used forklift.

Depreciation and Value Recovery

While depreciation cost lowers the asset's value, resale offsets part of the acquisition expense. A forklift resold for $5,000 after years of use reduces the total lifetime used forklift cost.

Recycling or Disposal

Even forklifts beyond resale value can provide returns through scrap or parts recovery, which further helps control the long-term used forklifts cost.

Total Hours & Utilization

Accurate hour tracking ensures fair cost allocation. A forklift that logs hours inefficiently may appear more expensive than it is, distorting the actual used forklift cost. Careful monitoring helps businesses understand how each used forklift supports operations and aligns with forklift maintenance planning.

Hour Meters

Hour meters measure "key-on" time versus actual work time. Misinterpreting this data can inflate hourly cost figures and lead to misjudging the true used forklift cost.

Utilization Rates

How often the forklift is actively used compared to idle time affects the cost per hour. Higher utilization spreads costs across more productive hours, lowering the effective cost of a used forklift.

Operator Efficiency

Skilled operators maximize forklift use while minimizing wear. This indirectly lowers the cost of ownership and reduces the long-term forklift maintenance burden.

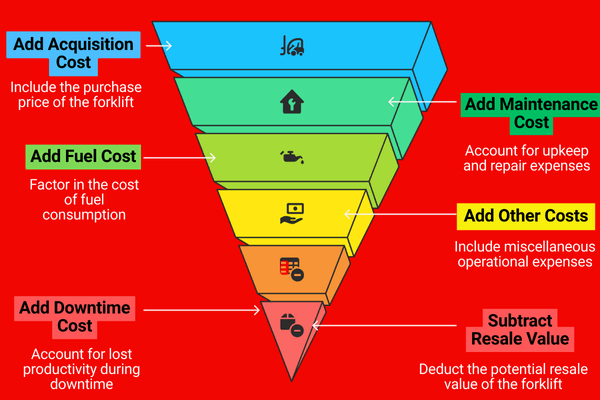

Putting It All Together: The Hourly Cost Formula

Once all factors are known, they can be combined into a formula to determine the real used forklift cost per hour. This ensures businesses capture every detail, including forklift maintenance costs and depreciation costs, instead of relying only on purchase price.

(Acquisition + Maintenance + Fuel + Other + Downtime – Resale Value) ÷ Total Hours = Hourly Cost

Example Calculation

Imagine a company buys a used forklift for $20,000. Over 2,500 hours, it spends $5,000 on maintenance, $7,500 on fuel, $2,000 on insurance and training, and loses $3,000 from downtime. After resale at $4,000, the calculation would be:

- Total cost = $20,000 + $5,000 + $7,500 + $2,000 + $3,000 – $4,000 = $33,500

- Hourly cost = $33,500 ÷ 2,500 = $13.40 per hour

This breakdown shows how forklift maintenance costs, downtime, and depreciation costs shape the final figure of a used forklift.

Tracking Over Time

Yearly tracking shows rising expenses. In Year 1, maintenance may be low. By Year 3, downtime and repairs often increase, signaling when replacement may be the better option and helping businesses reassess the used forklift cost.

Forklift Cost per Hour Calculator

Businesses can create a simple table to track costs year by year:

| Year | Acquisition + Depreciation | Maintenance | Fuel/Energy | Other Costs | Downtime | Resale Value | Cost/Hour |

| 1 | $6,000 | $1,000 | $2,000 | $500 | $500 | - | $10.00 |

| 2 | $6,000 | $2,000 | $2,500 | $500 | $1,000 | - | $12.80 |

| 3 | $6,000 | $3,000 | $3,000 | $500 | $1,500 | $4,000 | $15.20 |

This framework shows how costs rise and when replacement becomes logical.

What You Learn from Tracking Cost per Hour

Tracking cost per hour delivers useful insights for businesses seeking efficiency and guides decisions on when to buy used forklift equipment or continue operating current units.

True Cost Visibility

Rather than relying on purchase price, companies see the full picture of the used forklift cost, including ongoing expenses like forklift maintenance costs and downtime.

Smarter Replacement Decisions

Tracking shows that maintaining an older forklift outweighs the cost of replacing it with a newer, more efficient model. This makes it easier to determine the right time to buy used forklift alternatives.

Efficiency Gains

By identifying areas where forklift maintenance costs or operator training improves efficiency, companies save money both short term and the long term. Better planning lowers the total used forklift cost while improving productivity.

How Value Forklifts Helps You Lower Hourly Forklift Costs

At Value Forklifts, we've spent over 30 years helping companies manage equipment expenses. Our fully serviced used forklifts from trusted brands like Hyster, Yale, Cat, and Toyota are prepared to reduce downtime, simplify forklift maintenance, and keep overall used forklift cost under control.

- Inventory of 200+ propane, electric, and narrow-aisle forklifts.

- Nationwide shipping with expert consultation services.

- Reliable servicing supports minimal downtime and longer equipment life.

For businesses looking to buy used forklift equipment, we provide cost-effective solutions that balance upfront savings with lasting reliability.

Conclusion

Calculating the hourly cost of a used forklift means examining every part of ownership. Acquisition and depreciation cost, fuel and energy, insurance, training, and the full range of forklift maintenance costs all contribute to the real figure. Factoring in downtime and eventual resale value gives companies a clear and practical view of what their equipment costs. This perspective supports accurate budgeting, better replacement timing, and stronger operations. By tracking these numbers, businesses can make informed choices that improve both productivity and financial control.

Ready to improve your bottom line? Contact Value Forklifts today for expert advice and a wide selection of dependable used forklifts. Work with a trusted partner who can help you cut maintenance costs and keep your operations moving smoothly.

FAQs About Forklift Cost per Hour

How much does a forklift cost per hour?

- Depending on model and usage, a used forklift cost per hour typically ranges between $10 and $20, while new forklifts may cost slightly more.

How are forklift hours calculated?

- Forklift hours are measured using an hour meter. For a used forklift, it is important to know whether the meter tracks key-on time or actual work hours.

How many hours is good for a used forklift?

- A typical used forklift lasts 10,000–12,000 hours. Longevity depends on brand, usage, and forklift maintenance practices.

How much fuel does a forklift use per hour?

- Propane models average 1–1.5 gallons per hour, diesel slightly more, while electric forklifts consume less energy per shift. Fuel type is a major factor in used forklifts cost.

What is the average lifespan of a forklift?

- Most forklifts last 8–10 years or 10,000–12,000 hours, though this depends heavily on forklift maintenance cost, usage intensity, and depreciation cost factors.