How Much Productivity Are You Losing Each Day Without a Turret Truck Forklift?

Every warehouse works toward better efficiency, lower costs, and smarter use of space. Yet many operations lose valuable hours and resources each day due to outdated equipment. Without a turret truck forklift, facilities face ongoing productivity loss and wasted storage potential. This article explores the impact of missing this key equipment, how to calculate daily losses, and how a turret truck can enhance warehouse logistics and forklift fleet management.

The Hidden Cost of Operating Without a Turret Truck Forklift

Inefficiency often develops quietly. Idle labor, wasted travel, and underused storage space gradually drain resources. Without a turret truck forklift, these costs rise daily across shifts and departments, reducing operational output.

Each extra trip or delayed pallet move adds up over time. Losses vary by warehouse size, layout, and current industrial forklift types, but the pattern remains consistent. Facilities using only standard forklifts miss the hidden efficiencies a turret truck provides.

How to Estimate Your Daily Productivity Loss

You can estimate daily productivity loss without a turret truck by following a simple method:

- Measure cycle time: Make sure to track the time it takes to pick, move, and store your items.

- Compare with turret truck data: Use performance metrics from manufacturers or dealers.

- Find per-cycle savings: Subtract times to see the difference per movement.

- Calculate total loss: Multiply the time saved by the daily cycles and the hourly labor cost.

Formula:

Daily Loss = (Timeₙcurrentₙ − Timeₙturretₙ) × Daily Cycles × Labor Costₙhourlyₙ

Even a small time difference per cycle can create thousands in annual savings. Dealers can help verify these figures and provide realistic performance data based on real-world turret truck forklift operations.

How Turret Trucks Boost Productivity

A turret truck is built for Very Narrow Aisle (VNA) environments where every inch of space matters. These machines are designed for both precision and speed, helping to maximize storage capacity and enhance the efficiency of order picking. Adding a turret truck forklift can completely change how materials move within your warehouse.

Maximize Space and Capacity

A turret truck can operate in aisles just 5 to 7 feet wide, while traditional industrial forklift types need 10 feet or more. This difference can increase storage density by nearly 50%, allowing warehouses to store more pallets without expanding.

These forklifts also reach impressive heights, sometimes exceeding 14 meters (45 feet). That vertical reach transforms unused overhead areas into productive storage space. For growing operations, this capability increases throughput and postpones the need for costly facility expansions.

Speed Up Material Handling

The turret truck forklift has a 180° rotating mast that allows operators to access both sides of an aisle from one position. This design reduces turning, shortens travel distances, and speeds up loading and retrieval.

Modern warehouse logistics solutions often include guidance systems such as rail or wire technology that maintain straight, safe travel. Some models feature automatic positioning systems like Crown's Auto Positioning, which can boost productivity by up to 25%.

Increase Picking Efficiency

In high-demand environments such as e-commerce and pharmaceuticals, turret trucks enhance order picking efficiency. Man-up models lift the operator alongside the load, giving better visibility and control. This setup improves accuracy, reduces fatigue, and speeds up fulfillment.

Compared with man-down forklifts, turret models promote accuracy and faster operations. Their stability and controlled lift system make them an ideal choice for high-level picking.

What Is the Difference Between a Turret Truck and a Standard Forklift?

A turret truck specializes in tight-aisle operations, while standard forklifts are built for general use. Turret truck forklifts feature a rotating mast and compact design that allow them to function efficiently in limited space. Standard counterbalance or reach trucks need more room to maneuver, which limits storage density.

A well-balanced forklift fleet management plan often uses both types. Turret trucks handle dense storage sections, while standard forklifts cover loading docks or outdoor areas. Together, they create a versatile and efficient warehouse logistics system.

Safety and Daily Operations Best Practices

Safety and performance work hand in hand. Turret truck forklifts improve safety with guided navigation, strong visibility, and stable lifting systems. However, daily inspections remain a critical part of any operation.

What Must Be Done Daily Before Using a Forklift?

Before starting a shift, operators should inspect all industrial forklift types carefully. Key checks include:

- Brake and Control Check: Confirm brakes respond smoothly, steering feels steady, and the horn and lights work. This inspection prevents delays and helps maintain control in narrow aisles.

- Fork and Mast Inspection: Check forks, mast, and tires for bends, cracks, or excessive wear. Faulty components reduce load stability and can limit turret truck forklift performance.

- Hydraulic System Verification: Inspect hoses and cylinders for leaks, review fluid levels, and confirm smooth lifting and lowering. Reliable hydraulics prevent sudden stops and keep work consistent.

- Battery and Fuel System Safety: Verify that batteries are charged or fuel systems are sealed. Solid connections maintain consistent power and prevent unplanned downtime.

Following OSHA's inspection requirements supports safety and reduces equipment downtime, strengthening long-term forklift fleet management results.

What 65% of Impacts Involving Forklift Trucks Were With

About 65% of forklift collisions involve fixed objects like racks or walls. In tight areas, poor visibility and wide turns are common causes. Turret truck forklifts reduce these risks with rotating forks and guided steering that keep movement precise. Better visibility and compact design make daily warehouse logistics smoother and safer.

What Is the 3-Foot Rule for Forklifts?

The 3-foot safety rule requires keeping at least three feet between forklifts and people, racks, or other vehicles. This spacing prevents accidents without slowing down work. In narrow aisles, turret trucks maintain safe distances automatically through their guided alignment and smooth movement.

The ROI of Investing in a Turret Truck Forklift

Investing in a turret truck forklift delivers measurable returns. From labor savings to improved space use, these forklifts make every square foot more productive. Companies adopting turret trucks often report stronger order picking efficiency and smoother warehouse logistics operations.

Labor and Time Efficiency

A single turret truck can often do the work of multiple standard forklifts. With its rotating mast and reduced travel distance, it saves time and reduces operator fatigue. Over months of use, this adds up to noticeable labor savings and more reliable performance, improving forklift fleet management.

Space Optimization and Cost Avoidance

Dense storage layouts supported by turret truck forklifts can eliminate the need for new construction. By maximizing current space, companies reduce capital expenses and maintain flexibility. This capability is especially valuable where property costs are high.

Affordable Upgrade Paths

Reconditioned turret truck forklifts provide strong value for businesses looking to improve without large upfront costs. These models perform like new and often come with warranty coverage. Trade-in and upgrade programs allow companies to modernize fleets while keeping budgets balanced. The result is higher productivity and better long-term forklift fleet management.

How Value Forklifts Help You Maximize Productivity

At Value Forklifts, we have spent 30 years helping organizations enhance warehouse logistics and reduce overhead. We focus on reconditioned forklifts that provide dependable performance and safety without new-equipment costs. Our mission is to help managers move products efficiently and cost-effectively.

Our Experience and Expertise

Our team has decades of practical experience in material handling. We match each client with the right turret truck forklift or other industrial forklift types for their needs. Since our first website launch in 1998, we've helped thousands of businesses strengthen forklift fleet management and improve warehouse layouts.

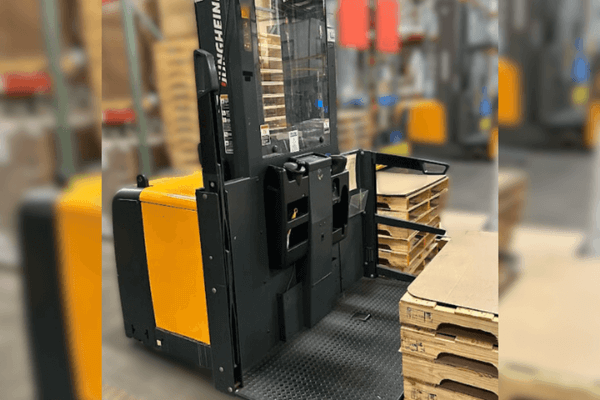

Our Offerings – Used Forklifts, New Quality

We offer more than 200 reconditioned forklifts from trusted brands such as Hyster, Yale, Cat, and Toyota. Every turret truck, forklift, and reach truck is serviced, painted, and inspected for lasting reliability. Our lineup includes propane, electric, stand-up, and VNA models ideal for compact warehouse logistics setups.

Used Forklifts – Like New at Used Prices

Our reconditioned units deliver performance comparable to new equipment at a fraction of the price. Each turret truck forklift is tested, refurbished, and backed by a service guarantee. Clients benefit from lower costs, reduced downtime, and improved overall efficiency in forklift fleet management.

Conclusion

Working without a turret truck forklift creates measurable productivity loss. By evaluating your current processes and upgrading to turret trucks, you can recover time, optimize space, and raise overall warehouse logistics efficiency.

Discover how much productivity your warehouse could regain today with a high-performance turret truck forklift.

Empower your warehouse with Value Forklifts. Contact our team today to find the ideal turret truck forklift for your operation and start saving time, space, and cost.

Most Common Questions:

Q: How much space can a turret truck save in a warehouse?

- A: Up to 50%, thanks to narrow-aisle design and high reach that support efficient warehouse logistics.

Q: Are turret trucks hard to maintain?

- A: No. Our reconditioned turret truck forklifts are thoroughly inspected, fully warrantied, and easy for us to maintain within a structured forklift fleet management plan.

Q: Can turret trucks work in mixed operations?

- A: Yes. We find that they pair perfectly with reach trucks or pallet jacks, allowing our customers to integrate them easily with various industrial forklift types in hybrid warehouse environments.